I love olives, any and all, and enjoy them alone, in salads, baked in bread, you name it. I also love a good olive oil and use it for nearly everything… even plain, for dipping bread. Mmm! When we first arrived in Amman, I was thrilled to find olive trees on the streets of our neighborhood being harvested. The local grocery stores have a wide variety of oils, and you should see the selection of olives in the delis! I tried a few oils, and eventually found Jordan’s Treasure Extra Virgin olive oil. Quite simply, it is good. It tastes great, it smells great. What a nice surprise then, when I found myself at the factory that produces it! Brian’s class sent home a last minute notice about a field trip, asking for permission and chaperones, and all I knew was they would be going to an olive farm and oil pressing plant; no details. I didn’t expect to be called to assist, as I chaperoned the last field trip and usually the number of spaces for parental companions are limited, but I lucked out.

First place we stopped, was a farm out near Jerash. This was a nursery, and the class was to learn about olive trees. One of the first things I noticed were the paintings and flags everywhere. Even this small building, probably a simple utility building, was displaying national pride… I like it.

The classes were given a tour of the greenhouses, and taught about two types of grafting. (From wiki:) “In stem grafting, a common grafting method, a shoot of a selected, desired plant cultivar is grafted onto the stock of another type. In another common form called budding, a dormant side bud is grafted on the stem of another stock plant, and when it has fused successfully, it is encouraged to grow by cutting out the stem above the new bud.”

The classes were given a tour of the greenhouses, and taught about two types of grafting. (From wiki:) “In stem grafting, a common grafting method, a shoot of a selected, desired plant cultivar is grafted onto the stock of another type. In another common form called budding, a dormant side bud is grafted on the stem of another stock plant, and when it has fused successfully, it is encouraged to grow by cutting out the stem above the new bud.”

This nursery was a very professional operation with temperature controlled greenhouses. Each greenhouse could grow about 210,000 small cuttings to be used for rootstock. We learned that it takes about 2 years to produce a small tree, ready to sell for planting.

Cuttings, planted to ‘root’.

The kids were also told about the importance of good soil, and the need to mix in crushed limestone, to keep the ground porous, and ‘bitmus’ (compost), to feed the young plants. We saw the greenhouses with more mature trees, and wandered around a little.

There were beautiful big trees to provide shade, and a lot of lovely flowering plants.

To get to the next part of the ‘class’, we piled back in the buses and headed to the main road. Then we stopped, because the bus got a flat tire… hmm? Fortunately, the driver had the tire changed in about 10 minutes, and we were on the road again.

I love to look out the window as we drive around. There were so many fruit stands alongside the road. I also saw potted plants, pretty pottery, honey, dried fruits, etc. Too bad we had no time to shop.

We drove through a small town…

Past (far off in the distance!) Ajloun castle…

I love this big blue door! Of course, I’d rather it be attached to a finished house, but you gotta start somewhere.

Eventually we arrived at the oil processing plant. We were told that, at harvest time in the fall, the farmers handpick the olives, and bring them to the plant to process. The plant processes the oil for the farmers to take for their own use, but also buys oil. This particular brand only uses organic grown olives. They also work with the farmers in order to obtain the olives at the peak of the season (when the acidity is the lowest) and ensure that the olives are handled with as less crushing as possible (which also keeps the acidity low). Extra virgin olive oil is obtained in this manner… the lower the acidity, the better. Apparently some farmers wait until the olives fall, but too far past the prime season, and the pH goes up. (I linked to the website, above… check it out as it’s very informative).

The olives are cleaned and debris removed.

The entire fruit is crushed, pits and all. Who knew? This plant uses a cold press method as heating the fruit destroys some of the flavor and aroma.

The oil, and a waste water, is removed from the pulp by centrifugal force, and the pulp is packed and dried into a dark wood-like substance - ?jift? – that can be burned like wood-pellets. (All these cool facts I never knew about olives!)

This was my view of Brian for most of the tour. Back to me, listening to our guide.

I was impressed to see the huge storage tanks. They had 5, 8 and even 20 ton tanks of oil! The plant was closed when we visited… everything was shut down, much was taken apart, and the employees were busy scrubbing and cleaning the facility and equipment. However, even though the pressing season is in the fall, they continue to package and ship the stored oil throughout the year.

What I buy at the store.

This brand, because it is certified organic and is produced to such a high standard, is endorsed by the crown and often given as gifts. I’d have to say, it’s a gift I wouldn’t mind accepting, it’s good stuff!

O wait, they did give us (adults) a little gift. Thank you!

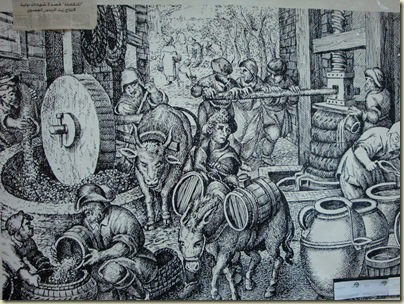

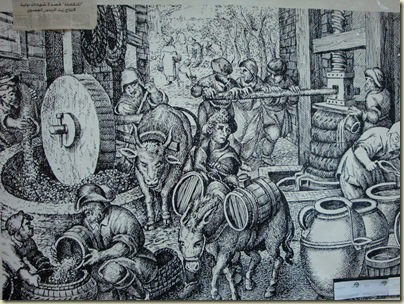

The children were shown a poster portraying an ancient method of pressing oil.

The children were shown a poster portraying an ancient method of pressing oil.

The engineer at the plant also showed how easy it was to chemically test the purity of olive oil as well. By that time though, we were running out of time and had to rush back to the school, so we didn’t hear as much about their laboratory, etc.

On the way back, I was able to catch a few more shots of the scenery… such a nice day!

Unfortunately the photo of the dresses was a bit blurry… I liked how the pretty fabrics looked in the sun, blowing in the breeze.

Some old buildings on a hillside.

Some old buildings on a hillside.

Ah… rooftops! I love the signs of life seen on rooftops. Yea… I did this in Cairo a lot too. I get this way about palm trees too.